- The filling machine suitable for the product must be selected taking into account the characteristics of the product. Volumetric filling machines are recommended for products with low flowability, such as honey and molasses, and filling cell filling machines for high quality products. Servo filling machines are recommended for bottom filling to minimize foaming on bubbling products.

- We have fully automatic filling machines with a capacity to produce up to 3,500 units / hour in companies with a large production capacity, but we also have single head and two-head manual filling machines for small scale companies.

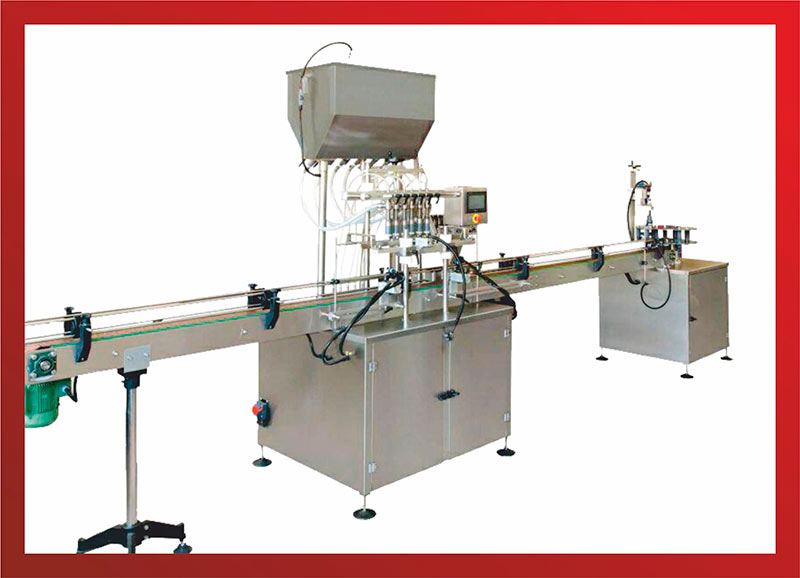

- Fully automatic filling machines can be produced as two, four, six or eight nozzles depending on the capacity requirement.

- Our machines can be filled from 100 ml to 1000 ml or from 500 ml to 5000 ml.

- Our filling machines fill with high precision (0.2%).

- The weight settings are made by typing the desired gram value through an electronic touch panel.

- Food, medicines, cosmetics, detergents, paints, beverages (without gas), etc. very different products can be filled in the sectors. As chemical materials; soap, shampoo, hand soap, softener, surface cleaner, gelatin, cream, paint, thinner, mineral oil, varnish, hardener, bleach, chlorine; food industry, such as honey, molasses, jelly, chocolate, ketchup, mayonnaise, oil, cream stirrer, drink (without gas); fruit juice, vinegar, water, mineral water, alcoholic beverages are some of the products that can be filled.

- Filling machine; Easy-to-use menus and ergonomic design. All configurations on the machine, inlet bottles, cutters, nozzle up and down, are easily controlled through the touch screen.

- Pumps, filling nozzles, contact surfaces and machine casing are made of 304 grade stainless steel.